- 20 Marks

Question

Ope-Olu Limited produces and sells household items. For a particular product, the marketing department has prepared the following quarterly expected demand for next year:

| Quarter | Expected Demand (Units) |

|---|---|

| 1 | 400,000 |

| 2 | 440,000 |

| 3 | 760,000 |

| 4 | 560,000 |

The existing production facility can only produce 540,000 units per quarter under regular time. However, it is possible to increase output by 40% if working overtime is introduced.

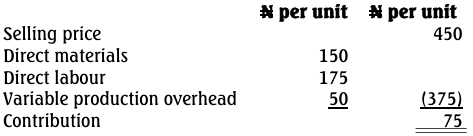

It is the policy of the company to manufacture units using a constant level of production system. This means that although the opening and closing levels of inventory for the year are zero units, there are increases and decreases in the quarterly inventory levels. Based on this policy, the unit selling price, variable production costs, and contribution for next year are expected to be as follows:

Additional Information:

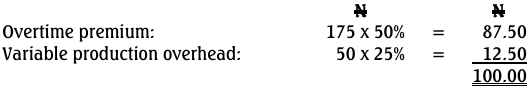

- Overtime is paid at 150% of the normal rate, and the unit variable production overhead cost will increase by 25% for those units produced during overtime.

- The company incurs a holding cost (based on average inventory) of N25 per unit per quarter for each item that is held in inventory.

- The company is considering switching to a Just-in-Time (JIT) production system due to fluctuating sales demand.

Required:

a. Discuss generally, the key conditions that are necessary for the successful implementation of a JIT manufacturing system. (7 Marks)

b. Calculate the cost of holding inventory for each of the quarters and the year in total under the current production system. (6 Marks)

c. Calculate the financial impact of changing to a JIT production system. (7 Marks)

Answer

a. Key Conditions for Successful JIT Implementation

- Reliable Suppliers: Suppliers should provide high-quality raw materials and deliver on time to maintain low inventory levels.

- Efficient Production Processes: Production processes must be well-coordinated to respond quickly to demand changes without excess inventory.

- Employee Training: Employees should be trained in lean practices to manage quality control and reduce waste.

- Close Supplier Relationships: Establishing strong relationships with suppliers ensures quick responses to production needs.

- Reduced Setup Times: Minimized setup times allow the facility to shift production seamlessly without delays.

- Commitment to Continuous Improvement: The company should foster an environment that encourages process enhancements.

- Demand Forecasting: Accurate demand forecasts are crucial to plan production schedules effectively under JIT.

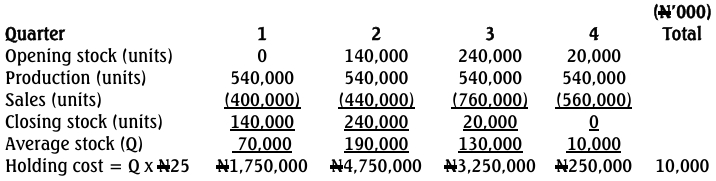

(b) Annual demand = 400,000 + 440,000 + 760,000 + 560,000 = 2,160,000 units

Annual capacity = 540,000 x 4 = 2,160,000 units

Thus, there is no need to work overtime under the existing policy of constant

quarterly production.

Calculation of cost of holding inventory

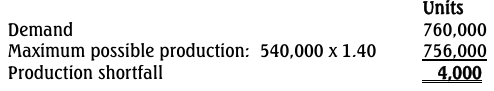

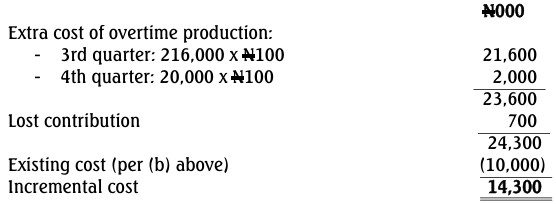

(c) JIT Production system

Sales demand for quarter 3 is above maximum capacity – including overtime capacity.

Contribution (4,000 units x N175 = N700,000) associated with the 4,000 units

will be lost.

Quantity produced during overtime

![]()

Extra cost per unit during overtime working

Financial impact of JIT

- Tags: Cost Analysis, Demand forecast, Inventory Holding, JIT, Overtime Production

- Level: Level 2

- Topic: Cost Management Strategies

- Uploader: Kofi